Filaments for 3D Printing.

What are and what are the most used Filaments for 3D Printing.

I Filamenti per la 3D Printing sono polimeri plastici che vengono utilizzati nelle stampanti 3D per creare oggetti tridimensionali.

There are many types of filaments available in the market, each with its own properties and characteristics.I filamenti più comunemente usati nelle Stampanti 3D FDM, sono il PLA (polylactic acid) e l’ABS (acrilonitrile butadiene stirene). Il PLA è un materiale biodegradabile ed ecologico, facile da stampare e ideale per i principianti. L’ABS è più resistente e resistente agli urti, ma richiede una temperatura più elevata per la stampa e può emettere vapori nocivi.Altri tipi di filamenti includono il PETG (glicole etilenico tereftalato), il nylon, il TPU (poliuretano termoplastico) e il policarbonato. Il PETG è resistente all’acqua e ai raggi UV, mentre il nylon è ancora più resistente e anche flessibile. Il TPU invece è ideale per la stampa di oggetti flessibili e il policarbonato è particolarmente resistente agli urti e anche alle alte temperature.Perché è importante saper scegliere il filamento giusto per il tuo progetto di Stampa 3D.

È importante saper scegliere il filamento giusto per il tuo progetto in base alle proprietà meccaniche e termiche che stai cercando.

In addition, occorre assicurarsi di utilizzare un filamento di alta qualità per evitare fastidiosi problemi durante la stessa Stampa 3D, come la bassa qualità dell’oggetto stampato, il possibile inceppamento della stampante e la rapida degradazione della qualità dello stesso oggetto finito.

I Filamenti Tecnici per la Stampa 3D

I cosiddetti filamenti tecnici sono filamenti più specializzati, progettati per la Stampa 3D di oggetti con proprietà specifiche, come la resistenza alle alte temperature, la flessibilità o la resistenza chimica.

Uno dei filamenti tecnici più popolari è il PEEK (polieterchetoncetone), noto per la sua elevata resistenza alle alte temperature e alla corrosione. However, il PEEK richiede una stampante 3D specializzata in grado di raggiungere temperature molto elevate e può essere costoso.

Un altro filamento tecnico è il PEI (polietereimmide), noto per la sua elevata resistenza chimica e termica. Il PEI viene spesso utilizzato nella produzione di parti resistenti all’usura e alla corrosione.

Il filamento in fibra di carbonio è un altro tipo di filamento tecnico popolare, noto per la sua elevata resistenza e leggerezza. Viene spesso utilizzato nella produzione di parti aeronautiche e automobilistiche.

Altri filamenti tecnici includono il PPSU (polisolfone polietersolfone), il TPC (copolimero termoplastico), il PETT (tereftalato di polietilene), il PCABS (policarbonato/acrilonitrile butadiene stirene) e il nylon rinforzato con fibra di vetro.

Scegliere il filamento tecnico giusto dipende dalle proprietà specifiche che si desiderano per l’oggetto finito. However, è importante tenere presente che i filamenti tecnici possono essere più costosi dei filamenti standard e possono richiedere una stampante 3D specializzata.

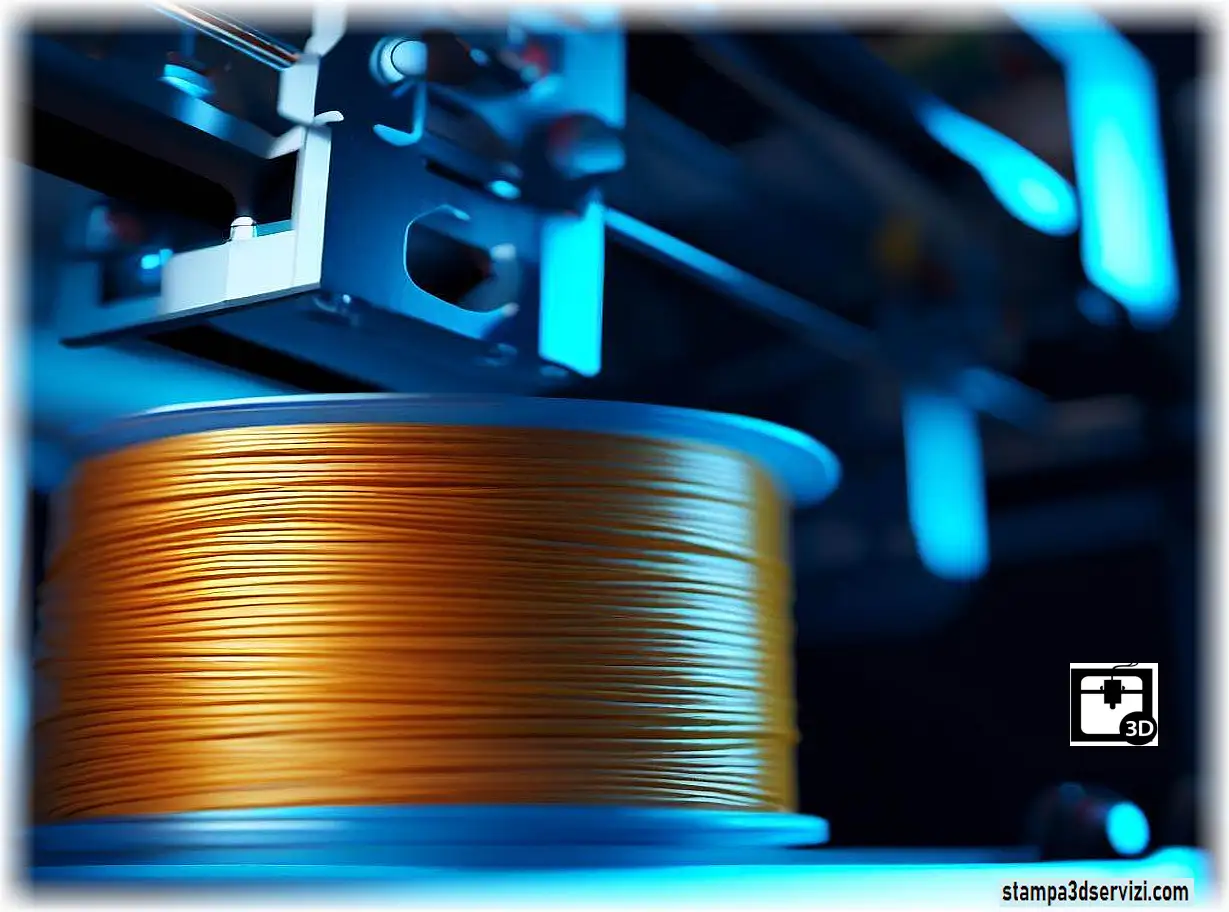

Come si producono i Filamenti per la Stampa 3D.

I Filamenti per la Stampa 3D vengono prodotti utilizzando diverse tecniche e materiali a seconda dell’applicazione. Generally, il processo di produzione dei filamenti prevede la fusione di materiali plastici, such as ABS, il PLA e il PET-G, che vengono poi estrusi attraverso una filiera per creare un filamento continuo. Il filamento viene poi raffreddato e avvolto su una bobina per la distribuzione.

Esistono diverse tecniche per produrre i filamenti per la stampa 3D, tra cui la produzione mediante estrusione a caldo o a freddo, la produzione mediante fusione a caldo e la produzione mediante estrusione a doppia vite. In addition, esistono anche materiali di stampa 3D basati su metalli e ceramica, che richiedono processi di produzione diversi da quelli dei materiali plastici.

Generally, la qualità dei filamenti per la stampa 3D è essenziale per la qualità delle stampe 3D. I filamenti devono avere un diametro uniforme e una buona adesione tra i diversi strati durante la stampa. Per questo motivo, i produttori di filamenti per la Stampa 3D effettuano rigorosi controlli di qualità sui loro prodotti per garantire che soddisfino gli standard richiesti.

i Filamenti per produrre Calchi con la Stampa 3D.

I filamenti per produrre calchi con la Stampa 3D possono essere realizzati utilizzando materiali come gesso, cemento o resina epossidica.

Questi materiali vengono mescolati con acqua o altre sostanze chimiche per creare una pasta e poi estrusi attraverso una stampante 3D. Una volta stampati, i calchi possono essere utilizzati per creare oggetti in vari materiali, come ad esempio la ceramica o il metallo.

Especially, i filamenti per produrre calchi in gesso sono molto comuni e vengono utilizzati per la produzione di modelli architettonici, prototipi di prodotti e persino per la produzione di manufatti artistici. La stampa 3D di calchi in gesso consente di creare oggetti con una precisione elevata e dettagli molto accurati, riducendo i tempi di produzione e migliorando la qualità del risultato finale.

Generally, la produzione di calchi mediante stampa 3D è una tecnologia in continua evoluzione e si prevede che diventerà sempre più comune in futuro, grazie alla sua capacità di creare oggetti con una precisione elevata e alla versatilità dei materiali utilizzati.