Improving CR-10 and Ender3 3D Printers

If you are passionate about 3D Printing And maybe you own or intend to buy one or more of these 3D printers: Creality CR-10, CR-10S, CR-10 Mini, CR-10 Ender-3 (First version or V2), this is certainly the “modification” that suits you. In essence, it is a simple upgrade that will definitely improve the print quality and reliability of your Creality printer.

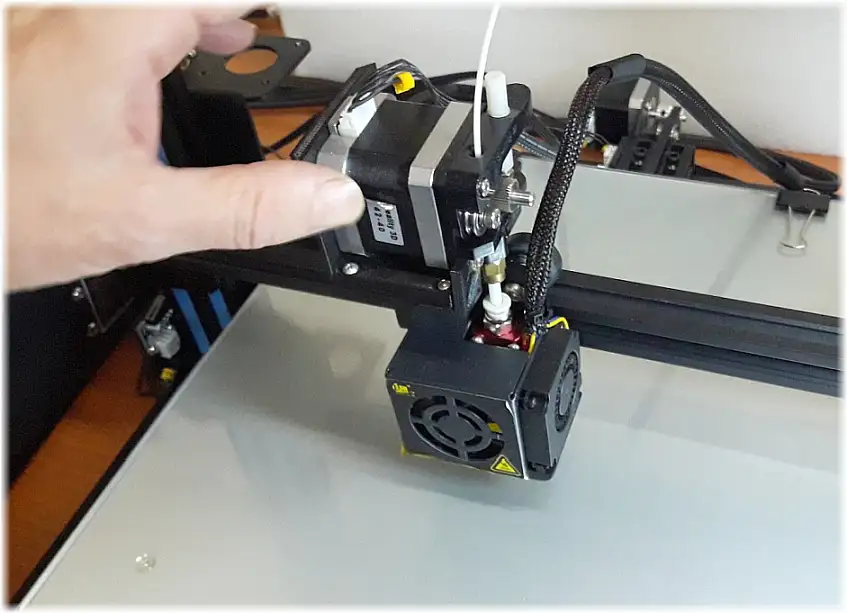

We customize the CR-10 with an effective Wade direct extrusion system.

The following question will arise spontaneously: What would be the advantages of returning to the use of the traditional direct drive system “Wade”, Although today almost all 3D printers have left it out ?.

The answer is the decisive improvement in the print quality and reliability of the 3D printer itself. In essence, the advantages of the Wide system consist in a much more homogeneous extrusion and also almost completely eliminates the possibility of incurring annoying hotend blockages.

In my opinion, the advantages mentioned above definitely overcome some small limitations of this technology which, on the other hand, are easily solved . Nevertheless, it catches the eye that today the most used extrusion system in 3D printers remains the “Bowden”.

Let's see what are basically the Pros and Cons of the two extrusion modes in the CR-10.

The substantial difference between the two extrusion systems concerns their positioning in the 3D printer. The Wade is positioned above the hotend and consequently moves with the trolley. The Bowden, on the other hand, is mounted separately elsewhere on the same printer, So the filament arrives at the hotend with a long path through a Teflon tube.

The main advantage of the Bowden is the low inertia of movement of the extruder along the x-axis. This characteristic becomes all the more important when the extruder makes fast movements subject to significant accelerations and decelerations.

The most serious critical issues of the Bowden extrusion system

In the case of the bowden system, the most negative aspect of this approach is that a higher force must be applied to achieve extrusion. This is precisely due to the considerable distance with the hotend, in fact, a part of the thrust that the filament receives from the driver is lost along the sheath. However, this technique allows us to significantly lighten the carriage allowing us to make faster and at the same time relatively more precise prints. In fact, since the motor and the extrusion driver are mounted in a remote position outside the carriage, the latter will have a very low weight and consequently its small inertia will allow it to move faster and more precisely.

The direct extrusion system “Wade”

The Wade being directly connected to the hotend and then mounted on top of the cart, it has greater weight and inertia. However, practical tests have shown that the weight obtained does not represent a serious limitation for printing.

The main disadvantage of an extruder is precisely the fact that the greater weight increases inertia on acceleration and deceleration. Instead, on its side we have that all the energy will be transmitted to the filament which will thus be able to escape with more force in the hotend.

In addition, the Wade system can be further improved by reducing its overall weight and consequently also inertia. In essence, it will be enough to replace the original Nema17 engine with a more compact and lighter one like the Nema14.

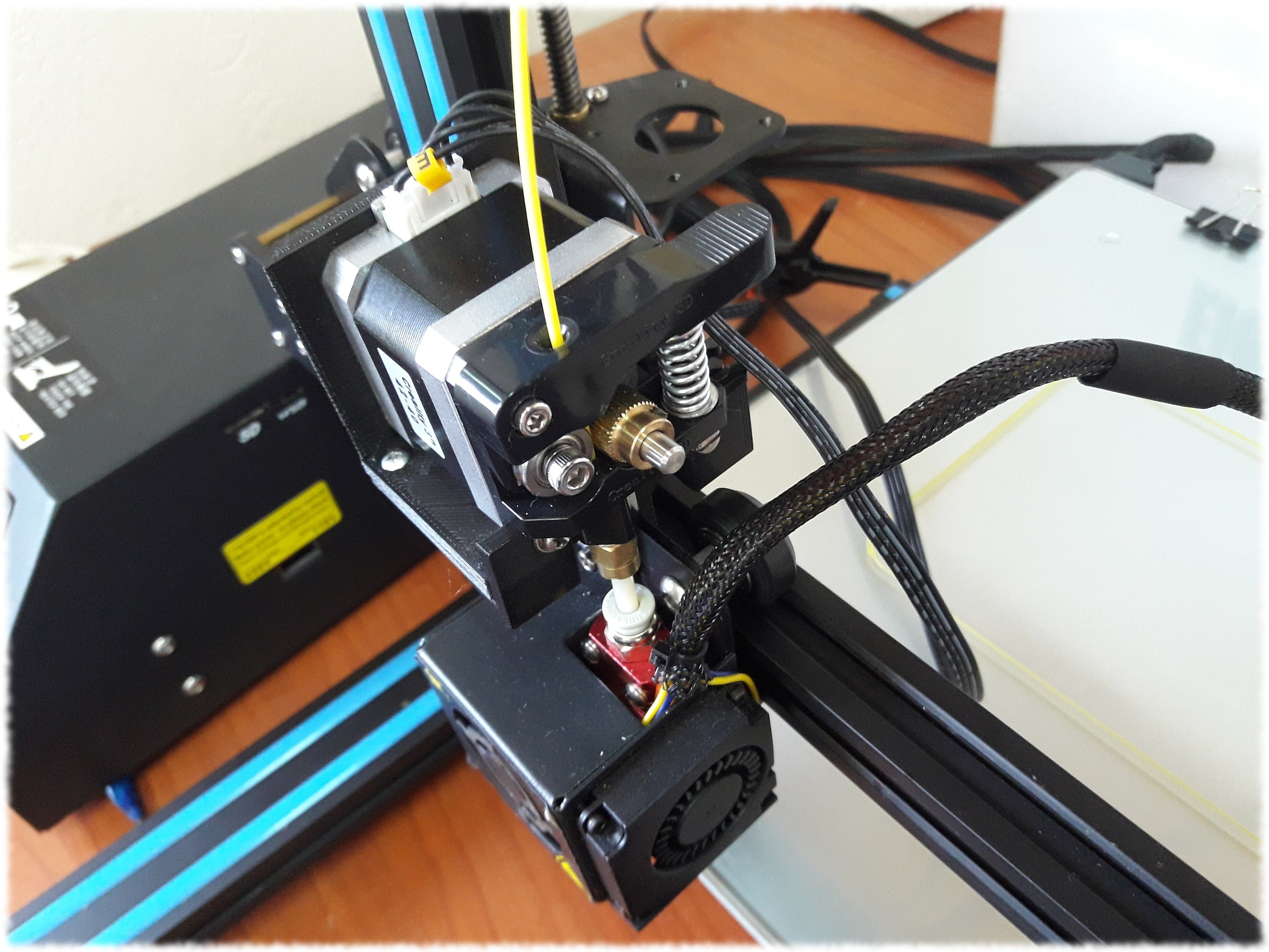

We reposition the motor directly on top of the extruder in the CR-10 3d printer.

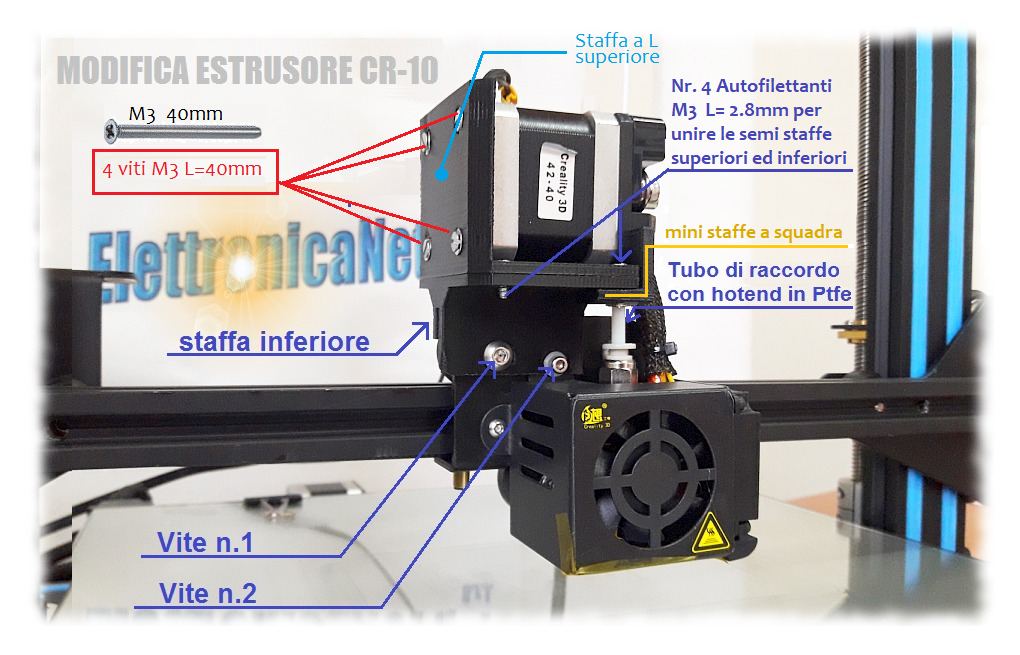

- Buy new ones Support brackets for CR10 for reassembling the motor in the new Wade direct extrusion configuration

- Disassemble the original extrusion drive by unscrewing the 4 screws that fix it to the front of the motor and at the same time also remove the filament end sensor

- Disconnect the connector that powers the original Nema14 motor and then remove it from the support plate by unscrewing the same 4 screws that also connect it to the extrusion driver.

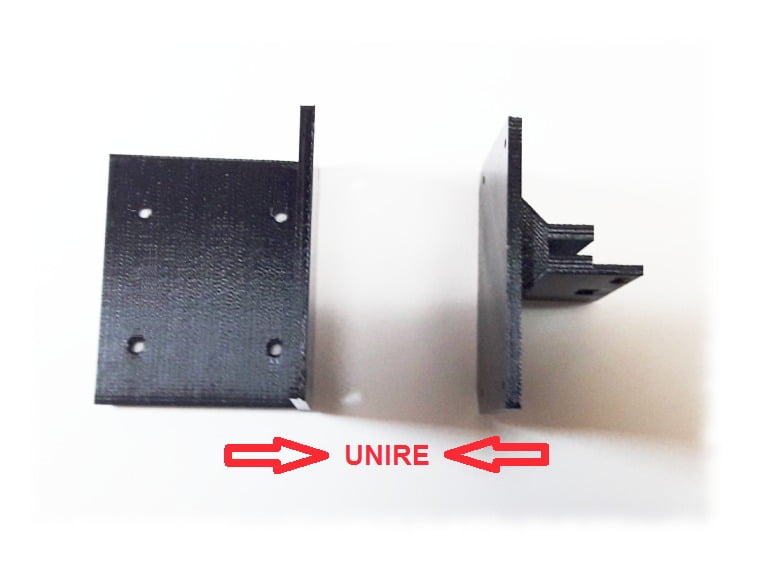

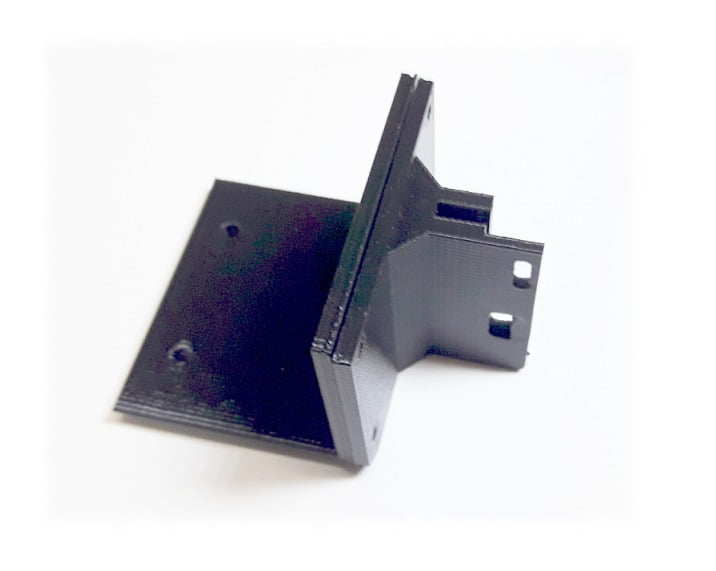

- Keep the 2 new support brackets handy, in particular now you will need the one in the shape of a team. Take the Nema engine, Remove the 4 rear studs and then place it on top of bracket no.1 using the same screws. You will have to match its rear side with the inner face of the same bracket and at the same time make the holes of the same coincide with those of the engine studs.

- Now join the two upper support brackets (1) and below (2), to form a single body using 4 self-tapping screws to lock them as shown in the following images.

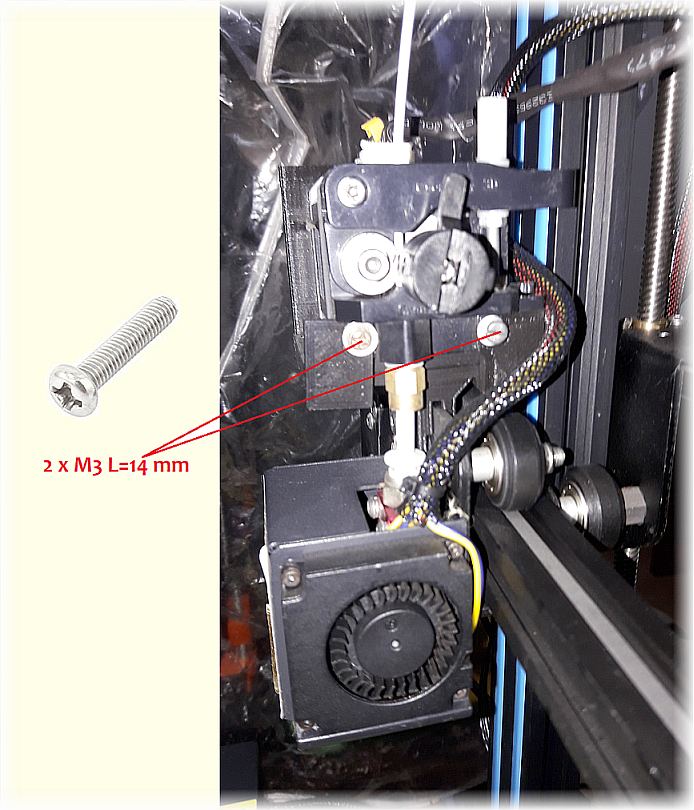

Now place the bracket assembly, motor and extrusion driver on the CR-10 print carriage, fixing it on the same using the two hexagonal head screws as shown in the photo below. The first on the left (1), is the one that secures the scroll wheel to the left of the print carriage. On the other hand, the second (2) it is the one that locks the box that supports the cooling fan in the same cart.

Once you have tightened screws 1 and 2 well, all you have to do is reconnect the power connector of the nema17 motor.

We are ready for a test print with the new extruder

Preheat the extruder and load the plastic filament by pushing down the drive gear pull lever down. Slide down the filament to the end of the filament’ hotend and therefore is close to being extruded. At this point, level the plate and start a test print to convey the results of the change made in practice.

To further improve print quality, I recommend replacing the original brass gear for filament drag. You can easily replace it with our special gear, which compared to the original boasts a much more effective grip. This is made of carbon steel and equipped with long sharp-profiled slats. This drastically reduces the risk of filament slippage and ensures a more homogeneous and vigorous extrusion during printing.

Later I will write a new article that will explain how to improve the extrusion driver by eliminating the spring that pushes the filament drag gear. The resulting benefits are not negligible…. Stay tuned.

Maurizio Licciardò

Cell.333 7602601