3D Printing | How does that work.

Cos'è e come funziona la tecnologia di Stampa 3D FDM.

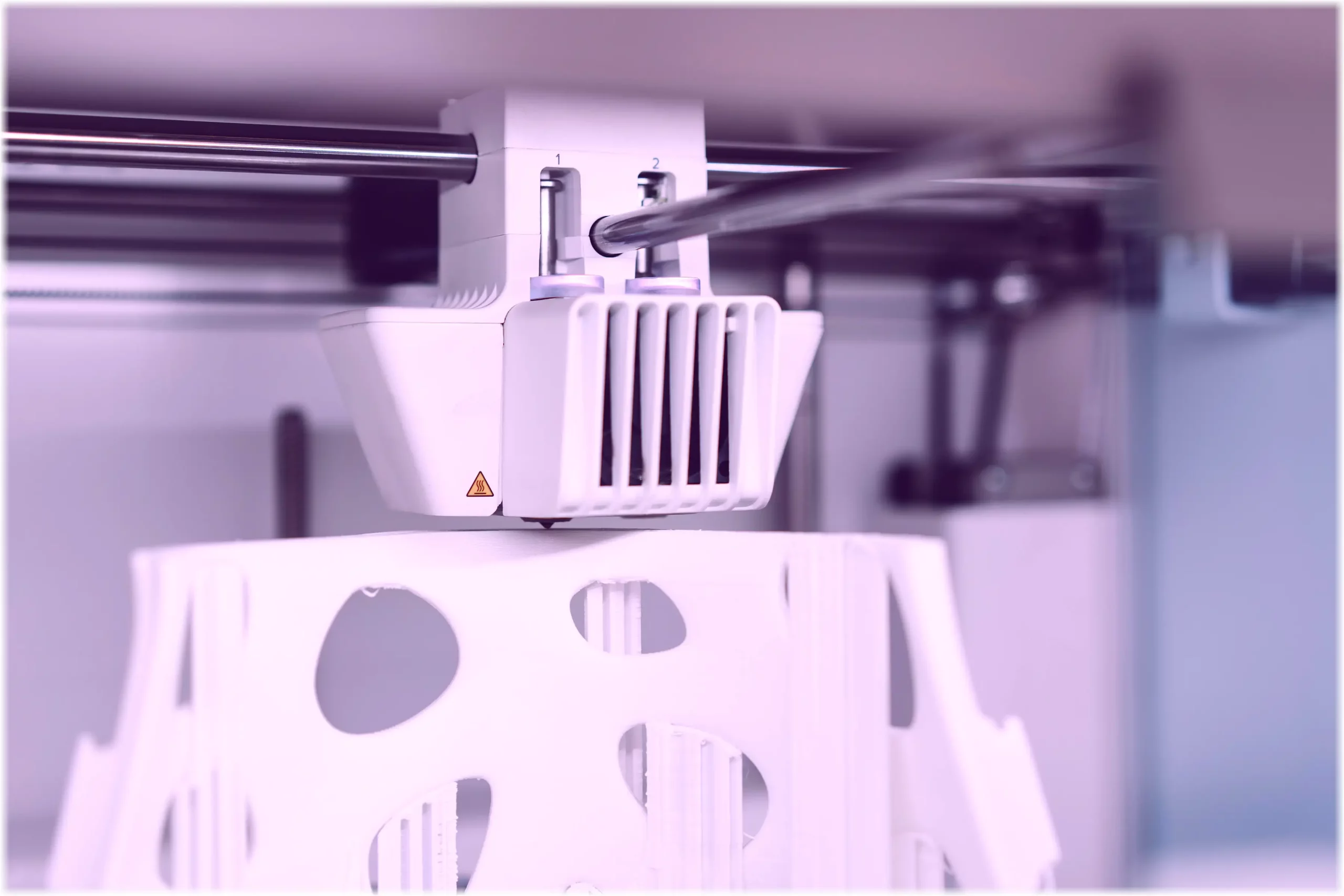

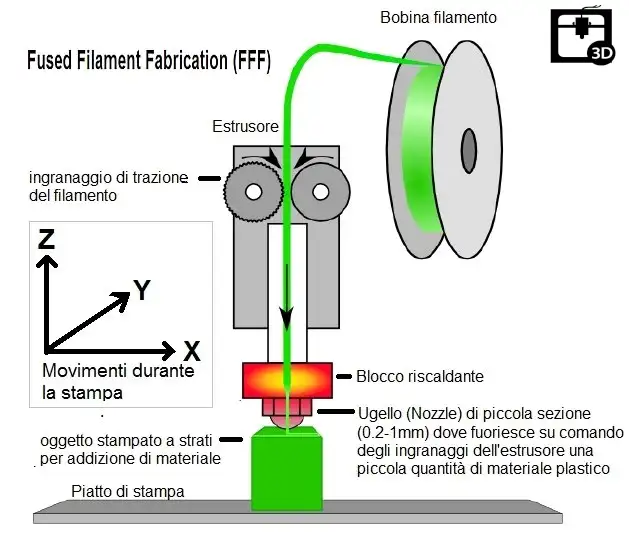

The most popular 3D printing technology, works with FDM technology, now renamed FFF (Fused Filament Fabrication), melting and extruding a plastic filament, through a thin nozzle called a "nozzle".

This specific technology 3D Printing So-called “plastic extrusion”, is the same that we mainly use in our FDM 3D printers .

In particular, it was developed by the open source community only starting from 2010, that is, when the patent of the relative owner had already expired.

The FDM system is therefore currently one of the most widespread and also the most economical way to print rigid and flexible plastic objects in three dimensions.

FDM 3D printers extrude molten plastic filament at between 180 and 300 °C.

The FDM 3D printer is used to compose a three-dimensional object by overlapping several layers of plastic material which together represent the volume of the object to be manufactured.

The materials that can be used for FDM 3D printing, are many and always evolving, in fact you can have different plastics, even particularly ecological ones such as PLA (polylactic acid).

It is a non-toxic and biodegradable polymer of plant origin, which allows you to easily produce finished objects, Good looking and large.

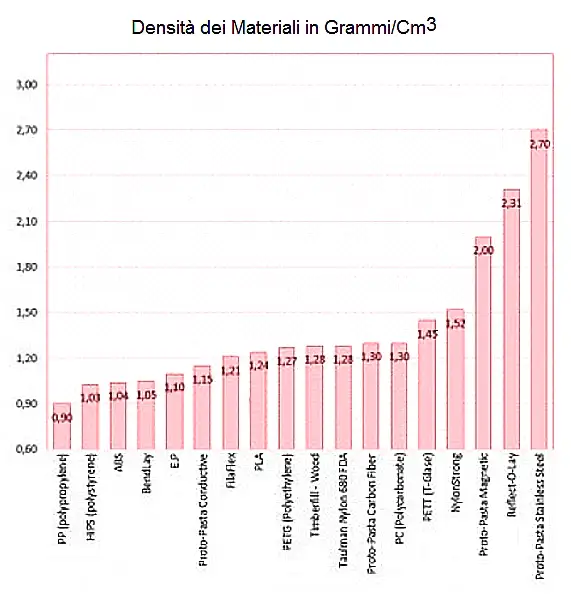

The Density of Materials for 3D Printing

Generally, different types of plastic materials can be used in FDM 3D Printing, shaped in the form of real filaments suitable for FDM 3D Printers.

Clearly the density of these plastics influences together with the type of polymer used, both the appearance and the physical and mechanical characteristics of the object that will be printed.

Learn more about the features of the most popular Filaments for 3D Printing Suitable for FDM extrusion printers, we refer you to the article of our BLOG dedicated to this topic.